Smart Factories

Smart Factories

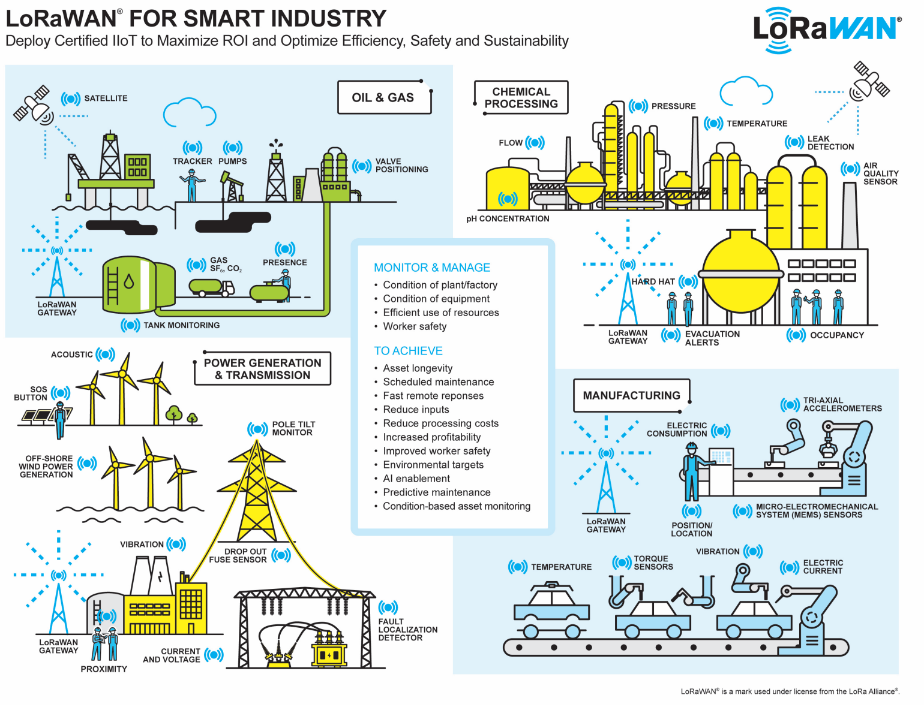

Smart Factories: Driving Industrial Efficiency with IoT

Key Features

- Real-time machine performance monitoring

- Predictive maintenance alerts

- Optimized production workflows

Benefits

- Reduced Downtime: Predictive maintenance ensures that potential issues are identified and resolved before they cause disruptions.

- Optimized Production: IoT data helps streamline manufacturing processes, reducing waste and increasing output.

- Improved Quality Control: Sensors monitor the condition of materials and products throughout the manufacturing process, ensuring high-quality output.

Smart Factories, also known as Industry 4.0, utilize IoT technology to create highly automated,

efficient, and flexible manufacturing environments. By connecting machines, sensors, and

systems, factories can collect and analyze vast amounts of data in real-time. This data-driven

approach enables predictive maintenance, where equipment issues are detected and resolved

before they cause downtime. Additionally, smart factories can optimize production processes,

reduce waste, and improve quality control. For example, sensors can monitor the condition of

materials and products throughout the manufacturing process, ensuring that standards are

consistently met. The result is a more agile, responsive, and cost-effective manufacturing

operation that can quickly adapt to changing market demands

Our Partners